Product Image

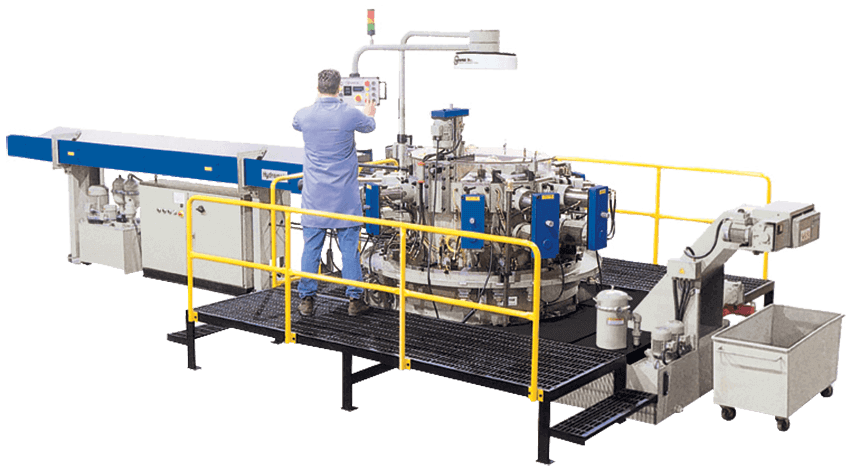

The HB 45-12 rotary transfer machine is a modular system consisting of up to 12 horizontal and 6 vertical toolspindle units rigidly mounted around a precision cast-iron ring. This arrangement has the capability of providing tremendous versatility and flexibility in a turn-key machining solution.

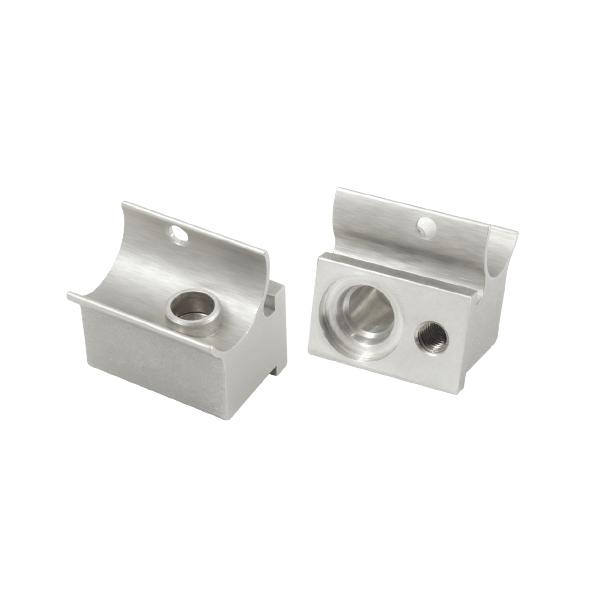

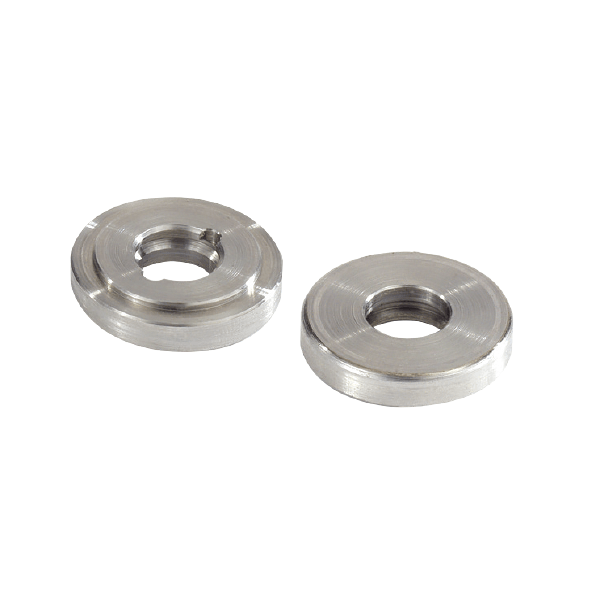

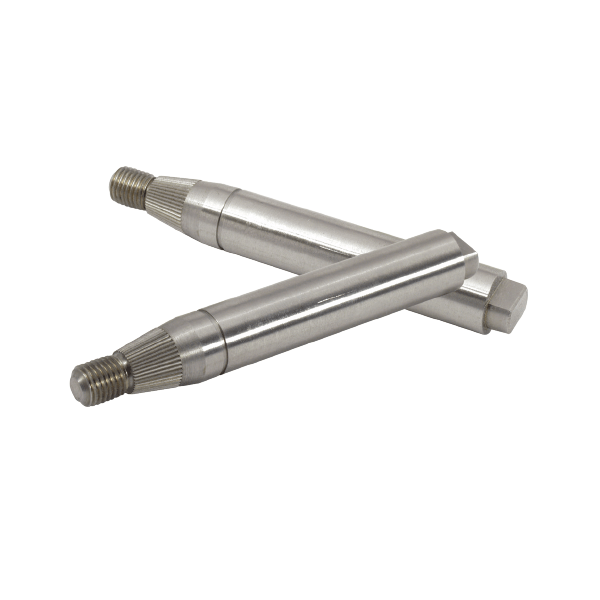

With 1-3/4" capacity, the HB 45-12 machine is ideally suited to produce parts from bar stock or blanks up to 6" in length.

Consistent high production & precise machining, combined with the elimination of costly secondary operations make the HB 45-12 machine an outstanding solution for cost-effective manufacturing.

Features

- Up to 12 horizontal & 6 machining stations

- Eliminates secondary operations

- Extreme accuracy and reliability of a Hirth ring

- Several different unit sizes available

- Coolant chiller optional

- Multiple loading and chip system options

Hydromat Advantages Over Conventional Machining

- Eliminates secondary operations

- Extremely short remnants and thin cutoff for significant material saving

- Reduces work in progress

- Increased productivity due to bar change and quick changeover capabilities

- Non-rotating bar stock provides quiet vibration free operation

- Modular tool spindles quick-change presettable heads for easy changeovers

- Easily adapted for vertical machining requirements - up to 6 stations

- Easily accessible operating controls and machine adjustments

- Coolant and chips contained in the tooling area away from motors and controls

- Precision table indexing and repeatability ensures accuracy with SPC to 2.0 CpK

- Inverting unit repositions part for complete end to end machining

Technical Specification Table

| Max Stock Size | ||||||||

|---|---|---|---|---|---|---|---|---|

| Rnd | Hex | Sq | Hor. Station | Vert. Station | Index Time | Weight LBS | Machine Power | Size Unit Options |

| 1 3/4" | 1 1/2" | 1 1/4" | 12 | 6 | 0.700 sec | 15,000 | 43HP (Avg) | 20/80 26/80 35/60 36/100 45/80 46/120 50/100 |

Saint Louis, Missouri

Saint Louis, Missouri