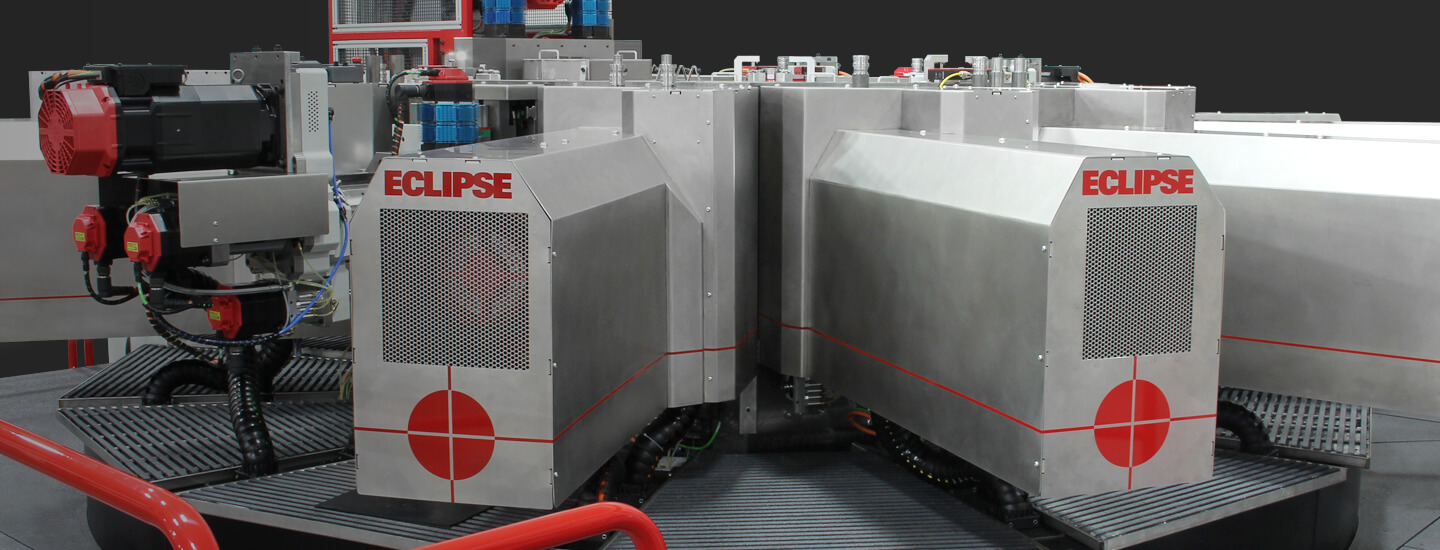

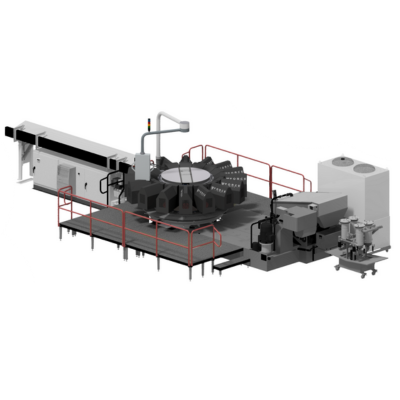

The FORCE CNC Rotary Transfer Machine Line is a fully electromechanical, ballscrew-driven system with direct drives. Available in 12 or 16-station configurations with collets or chucks, offering modularity with options for 1 through 4 axis

configurations: providing drilling, tapping, threading, thread milling, single point threading, profiling, and milling configurations: providing drilling, tapping, threading, thread milling, single point threading, profiling, and milling capabilities.

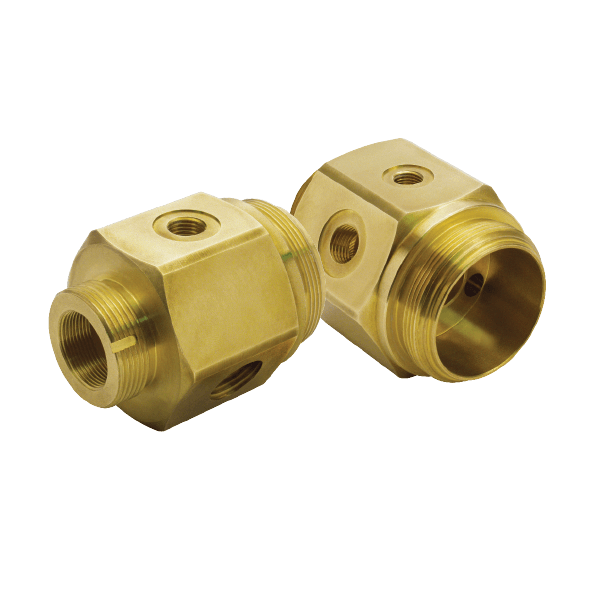

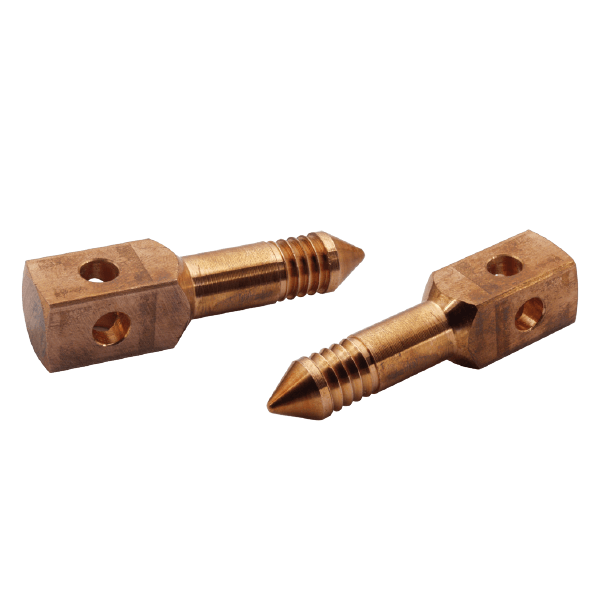

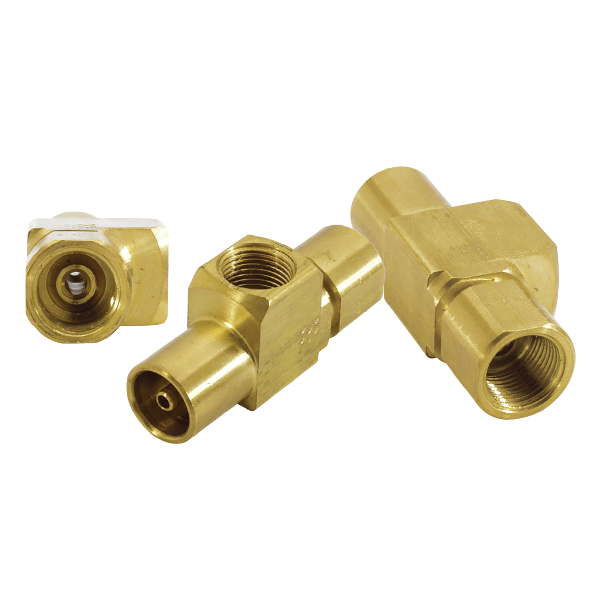

- Max. Stock Size:

Round 1.75", Hex 1.5”, Square 1.25" - Max. Part Length: 8”

- Stations:

Horizontal 16 | Vertical 8 - Index Time: 1.0 Second

- View EPIC HF Series

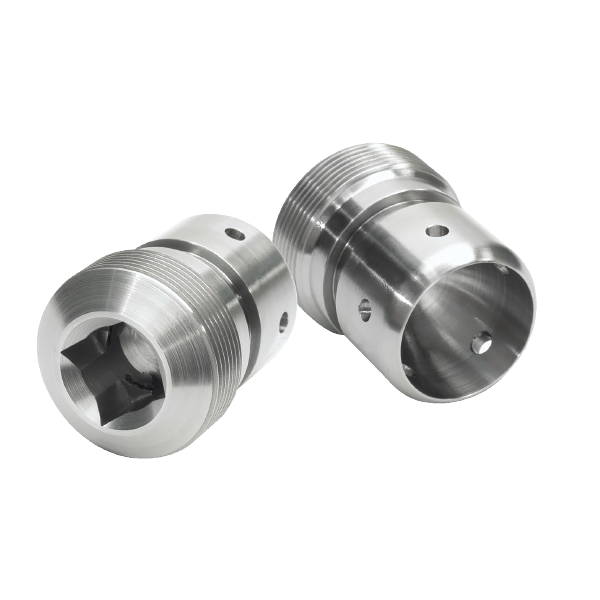

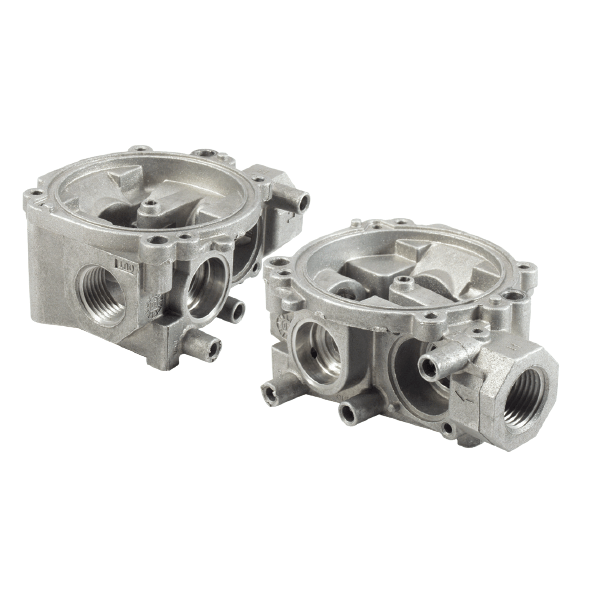

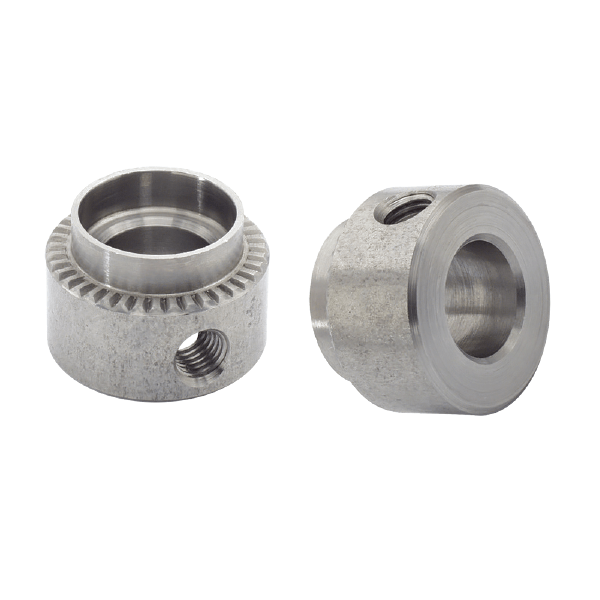

- Max. Stock Size:

Round 2.5" - Max. Part Length: 7”

- Stations:

Horizontal 12 | Vertical 8 - Material Capability: Bar and Blank

- View Eclipse 12-100

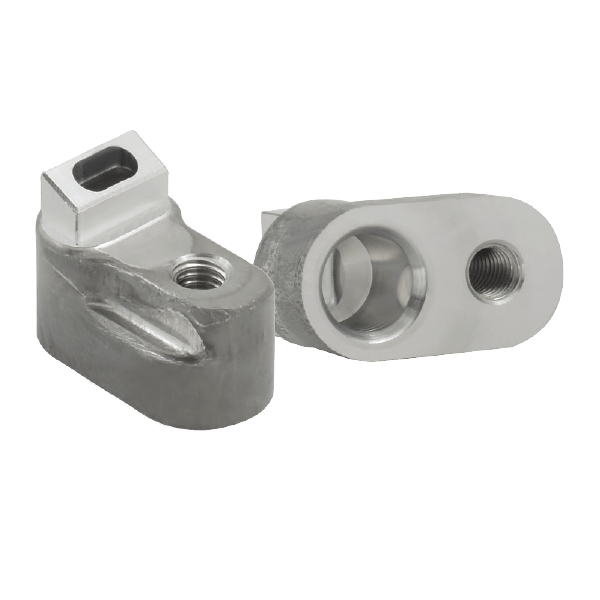

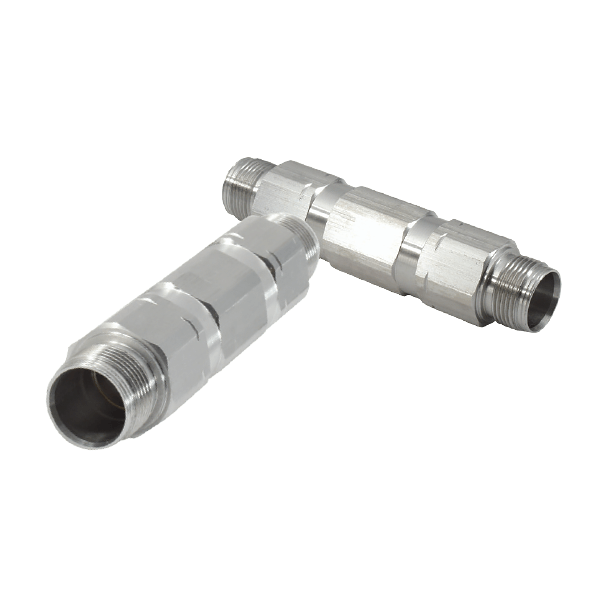

- Max. Stock Size:

Cube 10.00" - Max. Machining Units: Horizontal 4 | Vertical 4

- Max. Stations: 6

- Machining: 5 Sided

- View ICON Machine Series

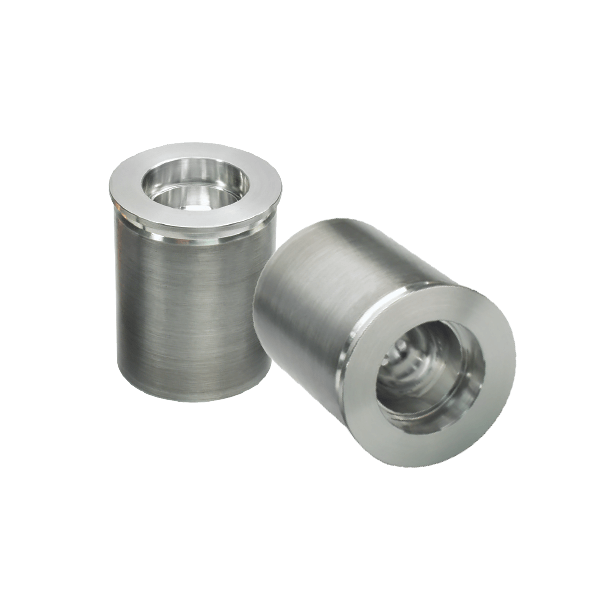

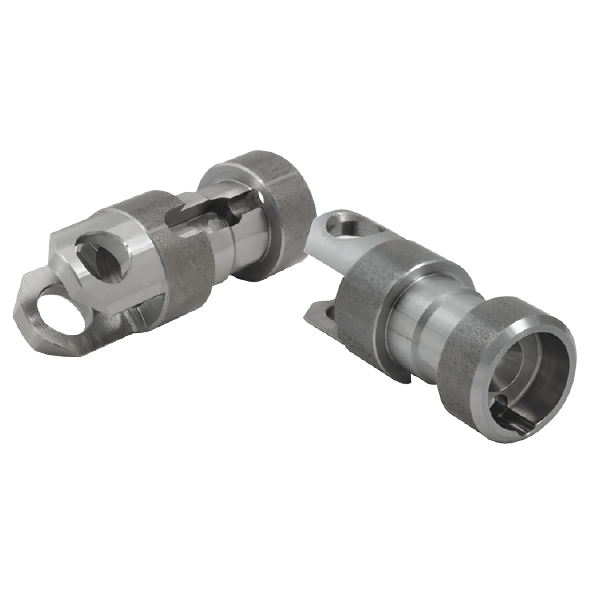

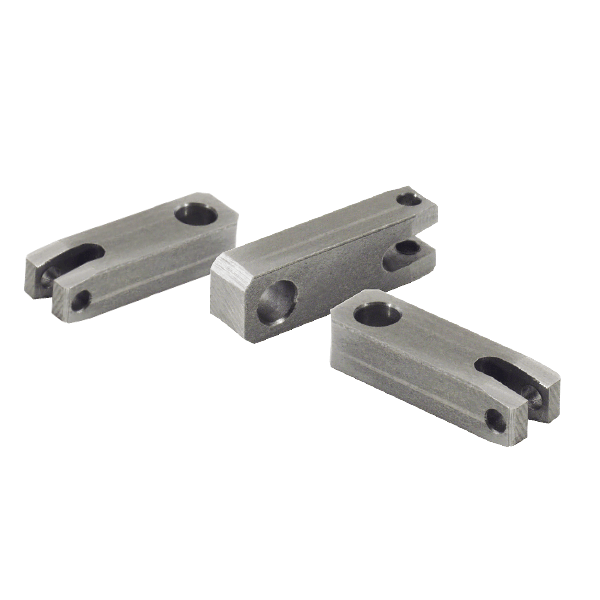

- Max. Stock Size:

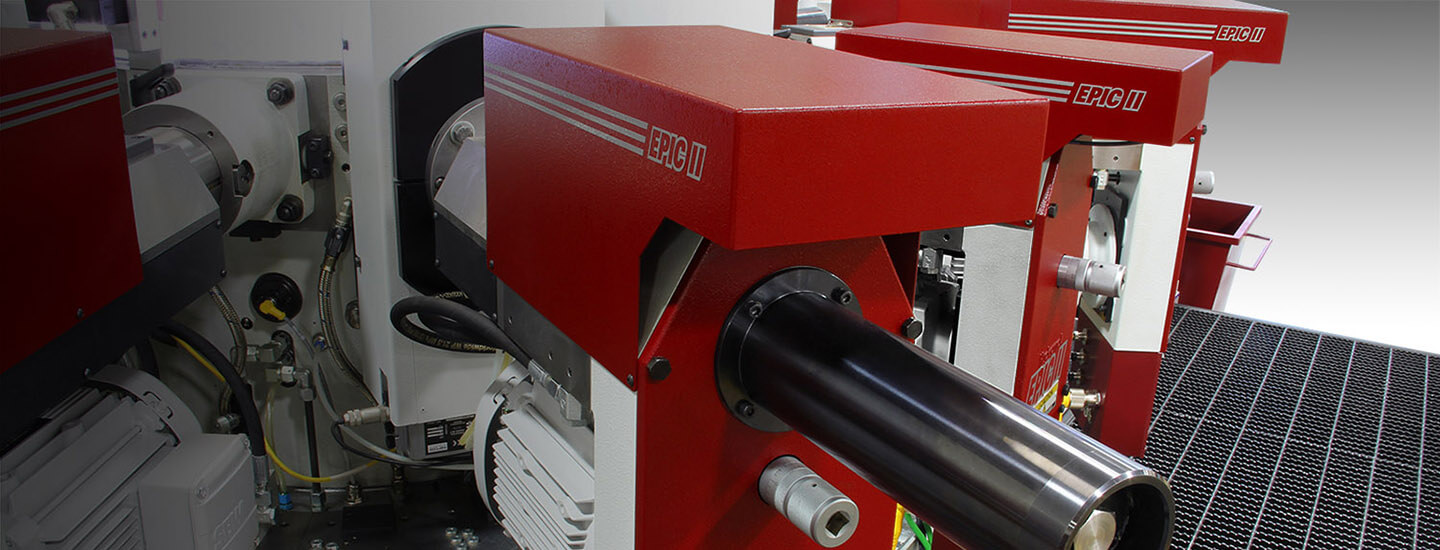

Round 1.75", Hex 1.5”, Square 1.25" - Max. Part Length: 6"

- Stations:

Horizontal 16 | Vertical 8 - Index Time: 0.9 Second

- View Force CNC Series

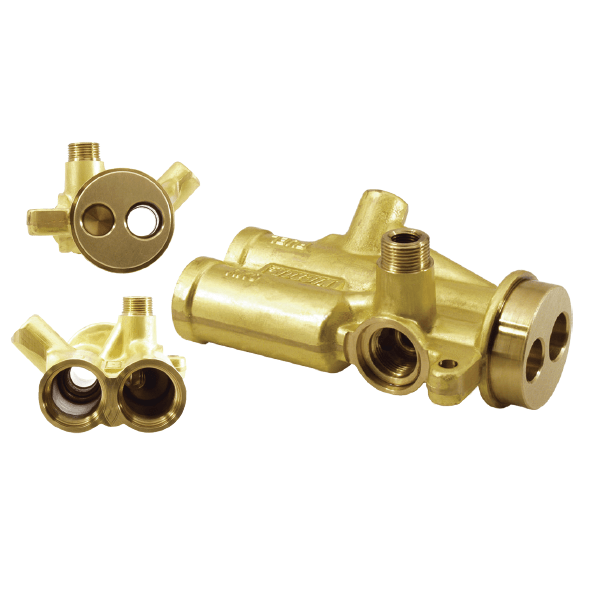

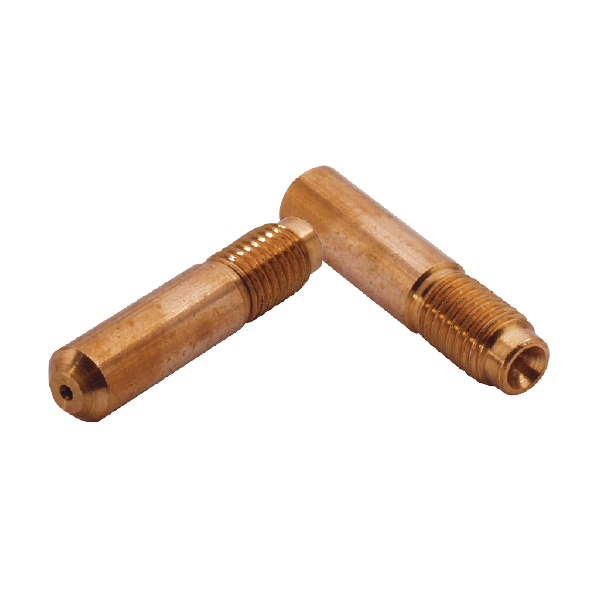

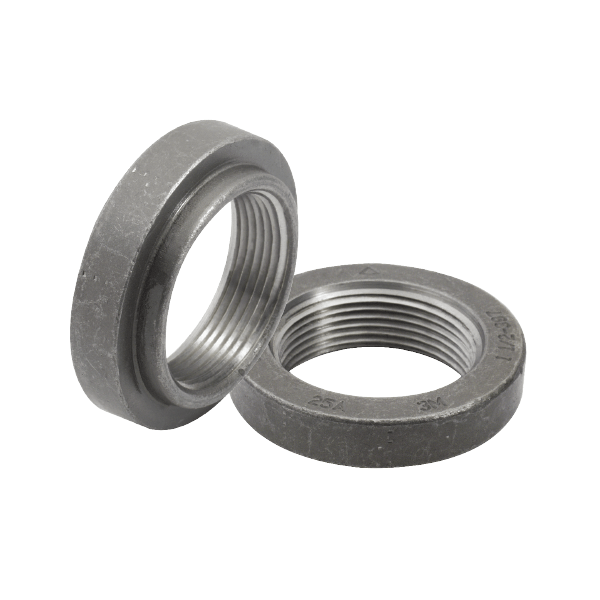

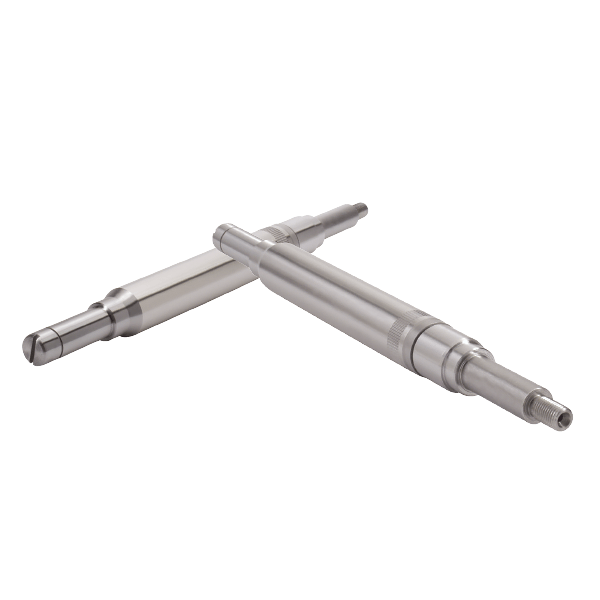

Click the image below to view individual application details. Arrows: scroll left to right

Saint Louis, Missouri

Saint Louis, Missouri